Nested Manufacturing Made Simple

The Revolution 180 works well in nested CNC processing environments. It is the only fully automatic contour bander which can edge directly to pre-shaped panels. The result is outstanding productivity gains.

Machine settings for each piece can be easily saved and then effortlessly retrieved on the console for production purposes.

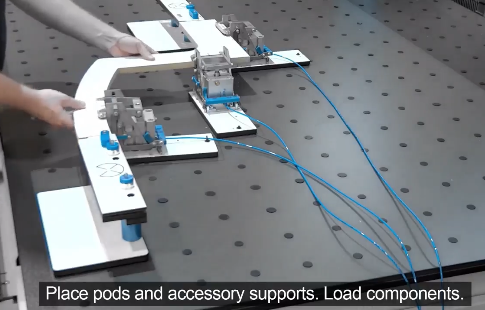

When installed, our projection system displays clear placement of the item and vacuum pods for even faster processing times.

We automatically edge-band and trim curved shapes and straight edge pieces without issue.

The Revolution 180 produces very high-quality edge-banded and trimmed components with no programming required. The machine operator on the floor is in full control of the process.

Components that are small or have complex shapes are easy to handle. We supply a range of accessory pods and clamps which are placed on the flat machine bed without the constraints of pod and rail table systems.

To illustrate capability this video has a very complex RV component being edge-banded. Set-up time is less than a minute using our projection system and production is effortless. No programming is required.

The Vector Revolution 180 sets the global benchmark for automatic edge-banding in nested CNC manufacturing environments.