Vector Revolution 180

Key Specifications at a glance

Field Size

X dimension 3,550mm

Y dimension 1,830mm

Panel Thickness

16 – 40mm

Minimum Radius

20mm external

50mm internal

Edge Thickness

Minimum 0.5mm with accessory thin tape kit

Minimum 1.0mm for butt joins

Maximum 3.0mm

Key Features

Machine Frame

The load carrying frame structure is fabricated from heavy plate steel and box section. It is extremely rigid and provides a wide stable support for the Y axis. All motion is carried on highest quality linear prismatic bearing rails.

Control System

The patented operating system is controlled by an intuitive icon-based touch screen PC with easy operating interface. The machine requires no programming, with the operator only required to make some simple selections such as the starting position.

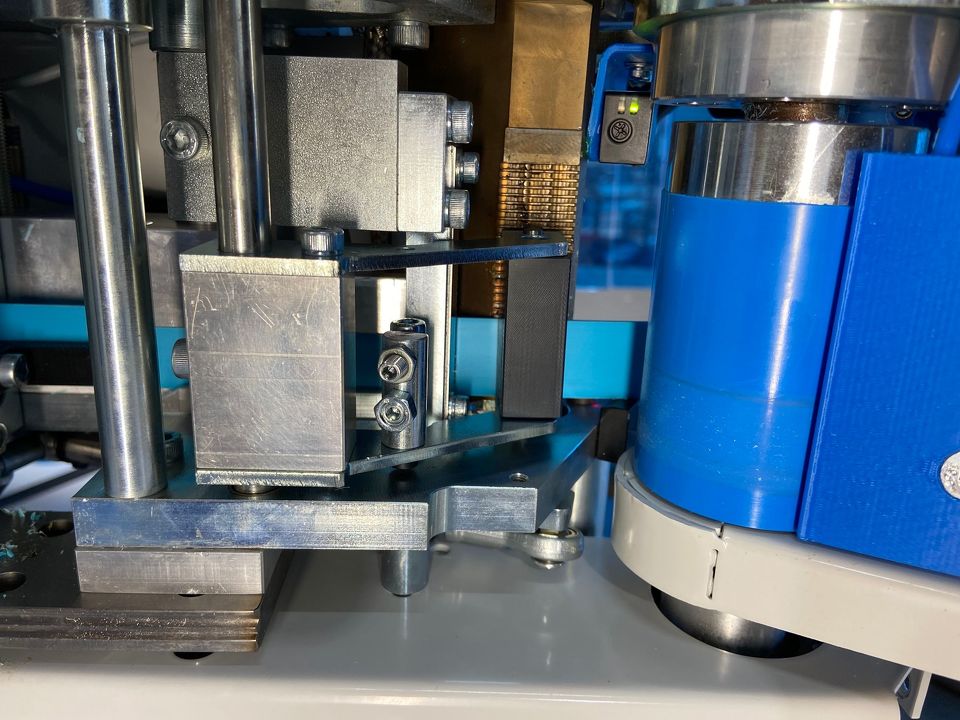

Edge Feed

The edge feed mechanism is mounted above the aggregate and coils around a simple winder mechanism. The edge is continuously fed and remains ready for the next workpiece as soon as the end cutter has cut the end of the previous piece. There is no need for expensive and complex edge feeding units to pre-cut lengths for each workpiece.

Trimmer & Surface Scraper

The VECTOR Revolution 180 incorporates a surface scraper in the trimmer unit. This unit operates using the patented SideWinder system and is performed simultaneously.

Cartridge Glue Nozzle System

The cartridge glue nozzle is a closed system which only heats the glue as it is used. From the heated face of the cartridge until it is extruded onto the banding, the glue is not exposed to the atmosphere to ensure no burning or discolouration. The original colour of the glue is maintained as are the glue properties.

Ease of Setup

Changing from one tape size to another is extremely simple with the operator only having to make a simple positive adjustment to the glue height, feed the new width of tape, and adjust the tape guide height. Glue height is set by positioning a pin in a hole in the index ring, removing any need for fine adjustment.

Vacuum Table

The workpieces are supported by means of vacuum cups sitting on a large flat bed. This enables absolute flexibility in positioning pods to ensure the workpiece is held securely.

Edge Joint

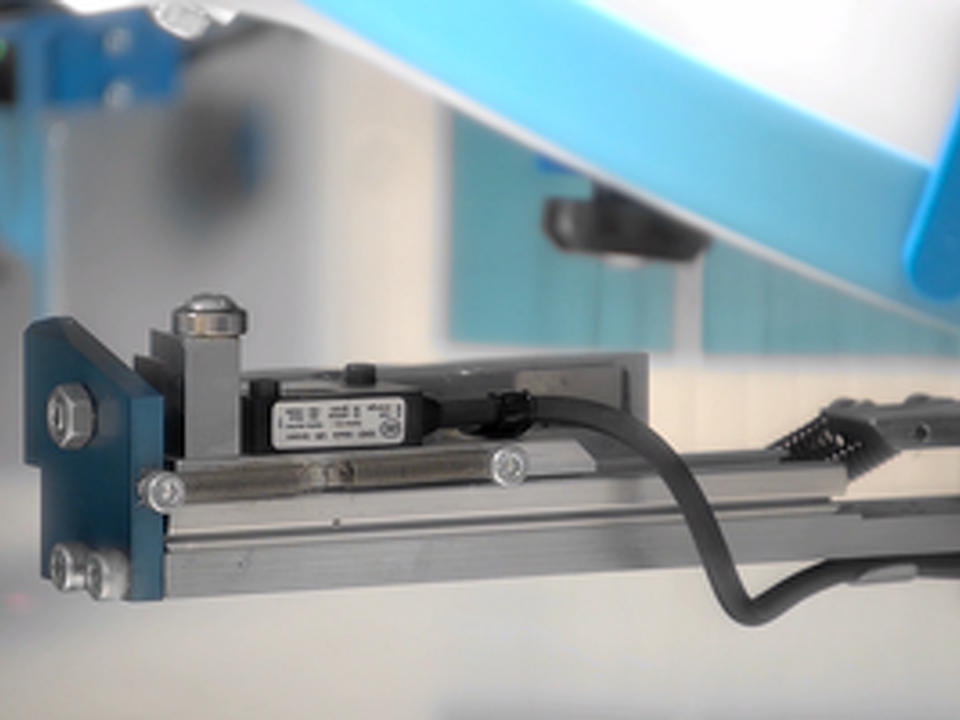

Where a complete 360 degree edging is required, the joint of the edge is controlled by a sensor arm. The speed of approach is automatically reduced at a precise distance from the joint and a sensor accurately detects the beginning of the edge which remained untrimmed at the cycle start. The trim cutter then cuts the edge with a bevel, the edge is applied and the top and bottom trimmed leaving a joint of the highest quality.

End Trimming of Square Cornered Panels

Where square cornered panels are to be processed the VECTOR Revolution 180 uses special EndPODS. These pods incorporate starting and finishing plates which simulate an extension of the workpiece. The advantage of this system is that it gives a reference for the panel placement and provides a straight edge to lay down the initial banding.

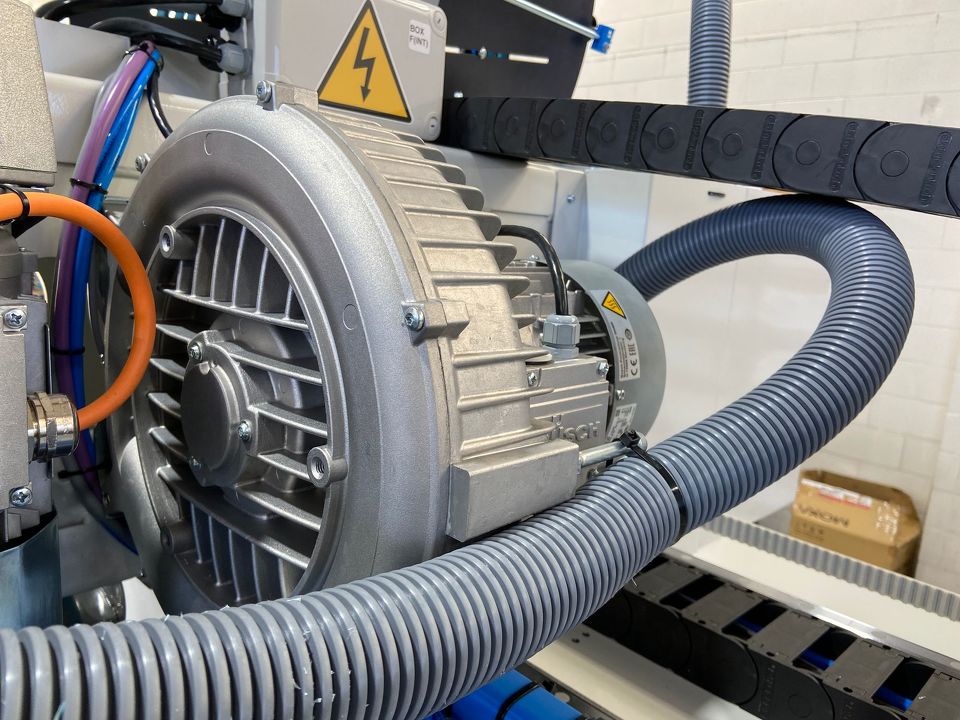

Power & Shavings Extraction

The shavings extraction is fully self-contained within the machine via a heavy duty 3 phase quiet operating vacuum fan connected to a filter box with an anti-static Teflon coated filter element. The filter box is mounted on the end of the carriage and is easily emptied.