Unlocking Potential

The processes you complete less often in

your factory require the deepest thinking.

Everyday actions are generally simpler, and practice refines processes. The

more infrequent jobs are more likely to upset the production team's workflow

and cause bottlenecks.

Also, your team shies away from selling and producing items that are not

regular or simple.

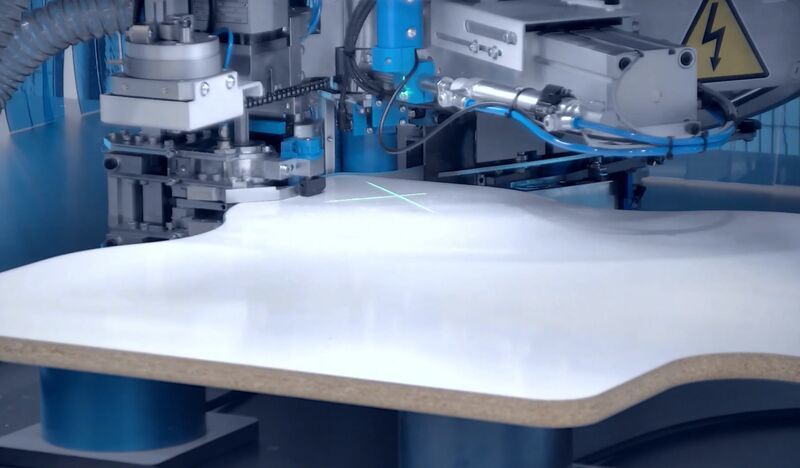

Contour edgebanding can fall into this category.

Factories that embrace contour edgebanding will differentiate themselves in the

market by accommodating more organic and customer-centric product designs and

generate production efficiencies that win more business.

A customer in South Australia has increased the proportion of contoured

products in production from 10% to over 30% in 18 months. Their customer base

expanded quickly, revenue surged, and the new ranges delivered much better

margins.

Their Vector Revolution has made contour edgebanding a seamless part of their

production processes.